Fabricating Your First Roll Cage?

Have you considered fabricating a roll cage on your own? Maybe you own a drag car that’s dipping into the low 11’s and now it needs a roll bar…or you’ve seen the exo-kart craze and want to build your own MiataKart or Vettekart.

Roll cage fabrication may seem like a daunting task, but when we found a wrecked Miata for only $200 we decided to give it a try. We had never attempted this level of fabrication before, but since the car was so cheap we had little to lose.

We’ll share everything we learned in the process so you can decide for yourself if roll cage fabrication is something you want to try.

We’re planning to apply everything we learn to build an NHRA 8.50 roll cage for the Chevelle too, so stay tuned for another article in the future.

Where will your car be raced?

The first question to ask is where you will race your car? The rules of that sanctioning body will determine how you build your roll cage. NHRA, SCCA, NASA, and Formula D all have different rules for fabrication, so you’ll want to study up and build to the highest spec possible. This is especially important when it comes to tubing material, size, and wall thickness.

Also, know that building a roll cage is a serious safety consideration. A cage can be less safe in a street car when you’re not wearing safety gear like helmets or safety harnesses. Using the wrong materials, poor design, and poor welding technique can result in a structure that’s fatal in an accident. Case in point, this Honda ‘death kart’ was involved in a simple traffic accident that ended up being fatal.

Does a Roll Cage Kit Already Exist for Your Car?

One more question to ask: are there roll cages or kits readily available for your car? If so, you can avoid a lot of time consuming fabrication.

As we’re planning out the future roll cage for the Chevelle, we’re finding that companies like Jegs offer pre-bent cage kits. The prices are nearly the same as just the raw materials to build our own. Being able to decide exactly where the bars lay will be the determining factor on whether we bend it up ourselves or buy a kit in the future.

Planning Your Roll Cage Build

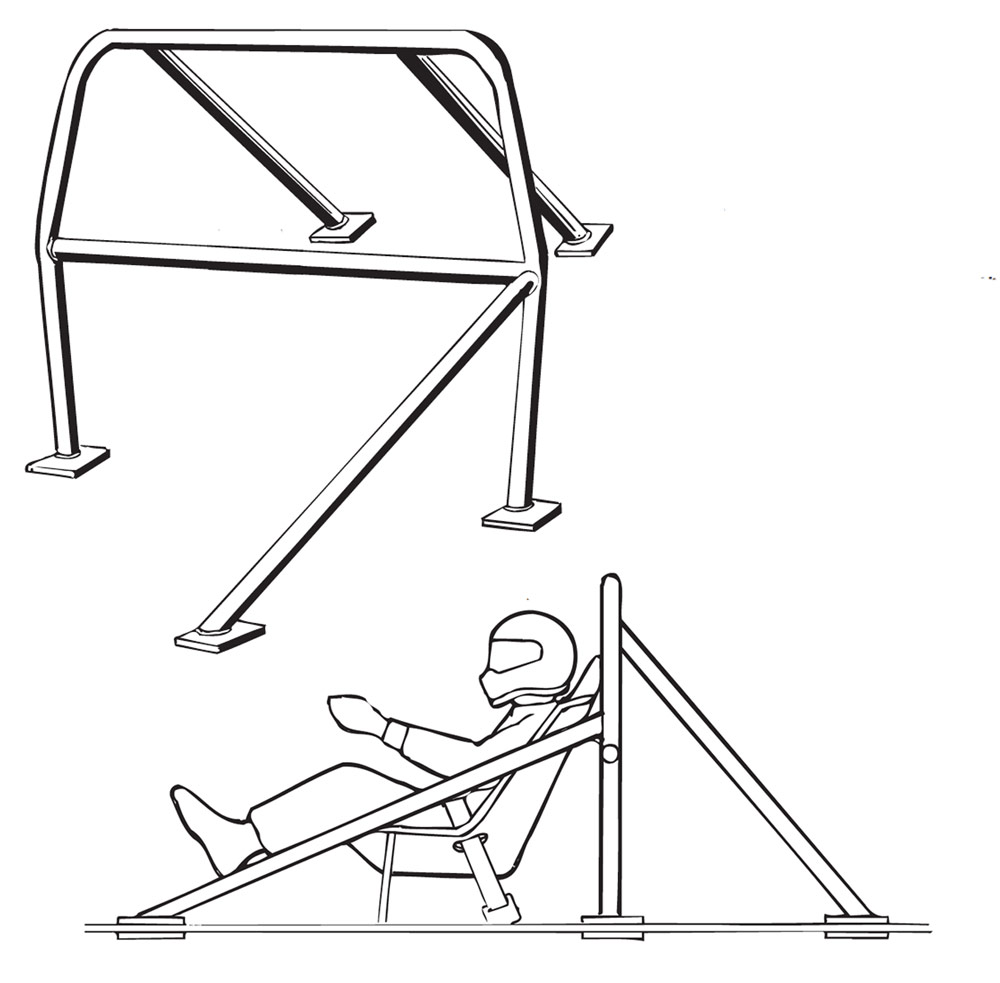

Since this was our first roll cage, we decided to start with the NHRA rules. We’ve spent the most time drag racing, and the rules are reasonably simple and easy to understand. After studying, it’s easy to see the progression of building a safe structure when you look at an NHRA 6 point roll bar. Then you build upon that by adding bars for an 8 point roll cage, then progress to an 8.50 or 10 point roll cage.

The next thing we looked at was the 24 Hours of Lemons website. Their guide, “How not to fail Lemons tech inspection” gives an easy to understand overview of roll cages, and what it takes to fabricate a safe and effective cage.

Looking at the lemons rules, it’s fairly easy to expand upon the simple concept of NHRA 6 point roll bar. You can start by adding either a main hoop, halo, or left/right bars to fabricate the full roll cage.

We also found a thesis written by a mechanical engineering student named Justin White on fabricating a Miata roll cage. It’s incredibly thorough and detailed, and provides a lot more information if you’re looking to dig deeper.

Roll Cage Design: Form vs Function

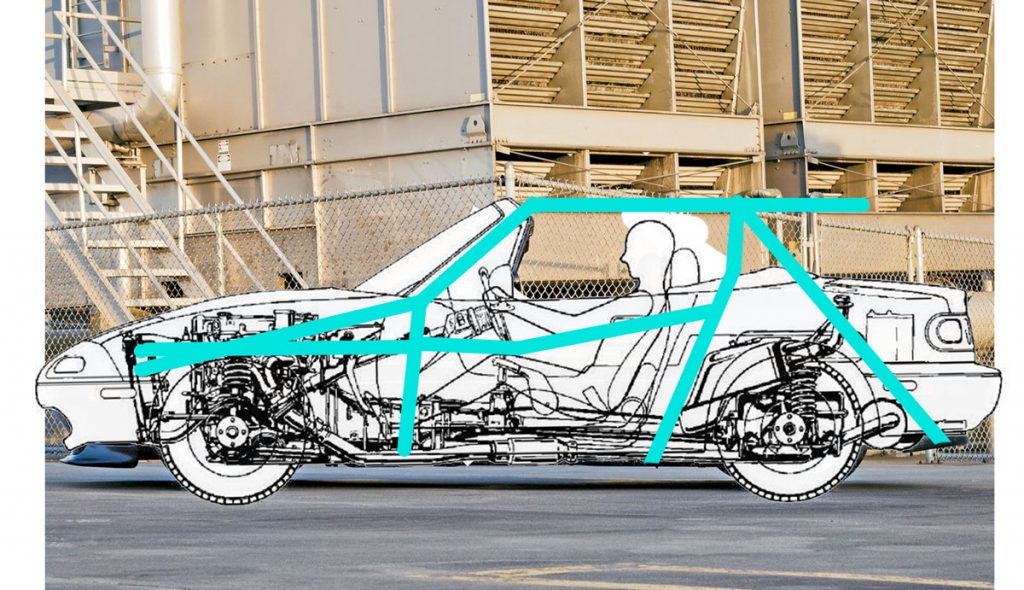

Our next step was gathering as many pictures and examples of exo-cage style cars as we could find. Since the main lines of this car depend on the cage structure, an artistic approach to the cage was considered along with safety.

After that, we got out pen and paper and then opened photoshop. We grabbed a picture of a Miata and started laying lines over the top to see what looked pleasing to the eye. Once we had the general concept in our head, we figured up how much material to buy and started gathering what we needed to complete fabrication of our roll cage.

Our overall approach to planning this build was to have a general idea of the shape, with room for creativity as we built. This meant we re-bent some bars and had to throw out some materials in the process. Your personality and tastes may dictate that you plan every inch, angle, and step in the process…but that’s not generally how we operate.

Gathering Your Roll Cage Materials

Mild Steel vs Chromoly

When building an NHRA roll bar, you have a choice between mild steel (1 3/4″ O.D x .118 wall thickness) or chromoly (1 3/4″ O.D x .083 wall thickness). For a full cage you can use slightly smaller tube (1 5/8″). The advantage of chromoly is strength — the tubing has a thinner wall but still provides the same strength, which means you save weight overall — sometimes 50-60 lbs total.

We opted for the larger size tubing so we only had to buy 1 die for our tubing bender. This gives us a choice of bending up either a roll bar or a roll cage on future builds. We also went with mild steel, mainly to keep the build on a budget. Chromoly requires TIG welding, which we don’t have much experience with. Using mild steel means we can use our existing MIG welding setup.

Frame vs Unibody

The Miata is a unibody car, so any attachment point needs to be welded to a 6″ x 6″ piece of steel thats .125″ thick and fully welded to the chassis. This prevents the bars from poking through the thin sheet metal in an accident. On a frame-on-body car like the Chevelle, the bars are welded directly to the frame.

There are provisions in the NHRA rules for using plates and bolts for mounting the cage, but we suggest you consult the NHRA rule book, or better yet, an actual person who inspects and certifies roll cages. You don’t want to build a roll cage that fails tech, risks your safety, or waste money on materials.

Get the Right Roll Cage Fabrication Tools

Tubing Benders

Next was to make sure we had all the necessary tools to build our roll cage, with the main tool being a tubing bender. Note that you CANNOT use something like a Harbor Freight pipe bender to build a cage. Those benders kink the pipe which isn’t acceptable.

For this build, we chose the Speedway Motors tubing bender for 2 main reasons:

- It’s the cheapest way to get a tubing bender, and

- Because of it’s design, you don’t have to mount it to the floor to operate it.

This makes the tubing bender portable — you can take it anywhere, set it on a table or on the ground, and get to work. Just make sure to get the proper size die for the tubing you’re using (1 3/4″ for a roll bar, or 1 5/8 for a roll cage).

Overall, we’ve been very pleased with this tubing bender, especially for the price. If there are any disadvantages they are:

- Bending the tube can be a slow process pumping the jack up so much, and

- To get a full 90 degree bend we had to readjust the hydraulic jack part way through the process.

You could potentially fix both these issues by replacing the supplied jack (just a simple 8 ton hydraulic bottle jack) with an air operated jack of similar size.

Other Roll Cage Fabrication Tools

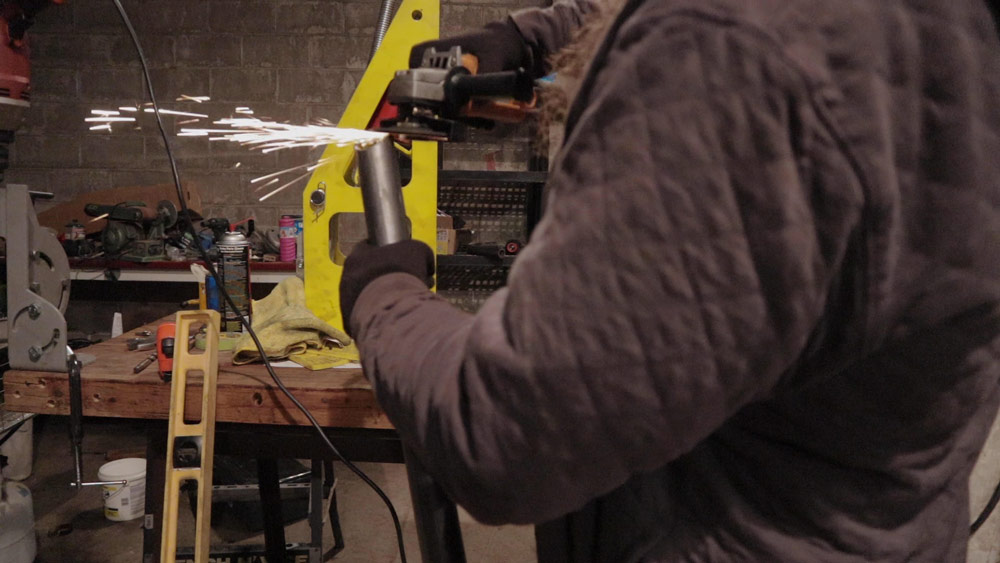

Having a good tubing bender isn’t enough. Just as important is a notcher. If the bars don’t fit tightly together, you’ll compromise strength, and your welds won’t be as effective. One important note: You’re not allowed to grind welds on any cage — you have to get them right or it will fail tech.

We picked up a tube notcher from Harbor Freight for $59. You could accomplish the job with an angle grinder as well, but it would take longer.

Other good tools to have are a magnetic angle gauge and an angle finder. Be sure you have plenty of grinding discs, cut off wheels, and brake cleaner for cleaning metal before welding — just make sure it’s fully dry before you weld to avoid toxic smoke.

Roll Cage Building in Action

You can see a preview of roll cage fabrication techniques as we scrambled to finish our Miata Kart in time for Zip Tie Drags.

Frequently Asked Roll Cage Questions

To sum up, here are some of the most popular questions that get asked about building a roll cage for the first time.

The best place to start is the rule book for whatever sanctioning body is over the type of racing you want to do. For instance, if you’re drag racing, you’ll want to a free 2020 NHRA rule book or buy a hard copy.

Most rules require mild steel or chromoly. The diameter and thickness of the material is determined by the sanctioning body and rules of your racing class, so consulting a rule book is necessary.

You could build a roll cage with just a mig welder, tubing bender, and an angle grinder, but the results may not be the best. For the process to go smoothly though, we recommend a metal chop saw, tubing notcher, angle finder, and a magnetic angle gauge. You’ll also need things to measure accurately like a tape measure, square, level, tape, sharpies, and maybe even some string.

No. The Harbor freight pipe bender is designed to bend metal pipe, which is manufactured to hold a volume of gas or liquid. A roll cage is made out of metal tubing, which is which is manufactured to be structural. The harbor freight pipe bender will kink as it bends, and may not be strong enough to bend tubing at all.

Conclusion

If you’ve done the research, planned out your cage design, and gathered the right fabrication tools, it’s time to actually start bending and welding up tube. Stay tuned for part 2 where we dive deeper and give tips and tricks on bending up the individual roll cage bars.

Join the discussion One Comment